Synthetic teak

Introduction

Deck refurbishing can be undertaken using a variety of materials and it is a matter of deciding which is the best choice for your boat and practical needs. Complex and large sized panels can be fabricated using our PVC synthetic teak strips to fit to almost any sized boat. These PVC materials have already firmly established themselves in the marketplace. Beautiful marine floors have a network of fitters and deck makers who exclusively use the Deckfab product. Simple deck panel fabrication is also possible using composite cork roll product where the caulking lines run the length of the roll. This permits small deck panel to be easily fabricated by simply cutting the material to shape.

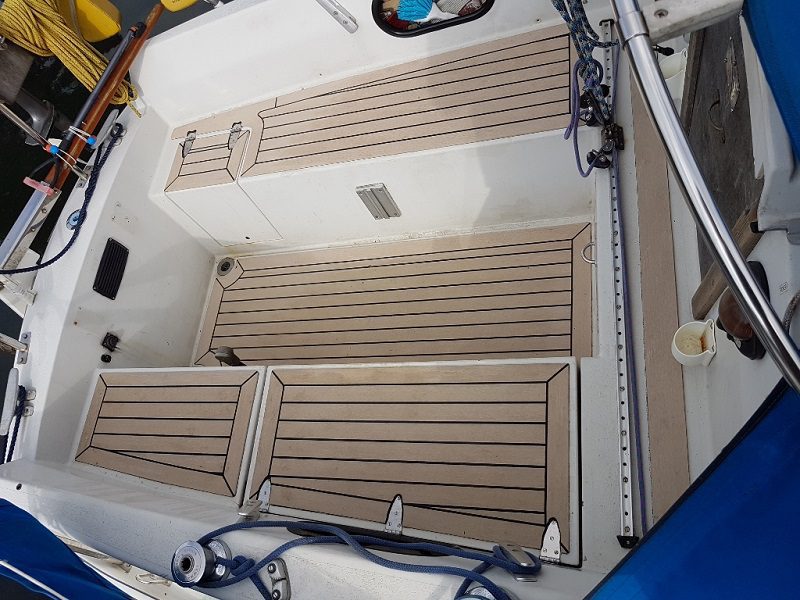

PVC Synthetic Teak

PVC Synthetic Teak surface texture resembles wood with a very realistic natural grain, making it almost indistinguishable from natural teak. We manufacture strips of varied and popular colour PVC extrusions in 20 metre length rolls. There are also extrusions for edge margining and wide plank for making border margins. These strips are used to fabricate synthetic teak deck products mainly for the marine leisure market. Our system is top and bottom welded on the margins and backwelded elsewhere making it the most durable on the market. We have been fabricating decks for 15 years and confident our system is the best on the market.

EVA Foam Synthetic Teak

EVA foam is a panel product that is made of a closed cell foam sandwich. To create a synthetic teak deck the top surface is a teak colour with a black coloured sandwich middle. To create the deck pattern a CNC router cuts the pattern on the surface. Consequently, templates need to be made or converted into a machine file for cutting. Panel sizes are restricted by the CNC machine so our sheet sizes are 2.4 metres x1.2 x 6mm. The material is excellent in warmer climates for sports boat, bathing platforms etc. Marine quality EVA foam is semi rigid and reasonably durable but not as durable as other quality synthetic teak materials shown here. For that reason our guarantees are limited to 1 year compared to 6 years with PVC. There are many inferior foams on the market that we consider as not really fit for purpose.

Rubber Synthetic Teak

Rubber composite is a roll panel product used to provide practical and durable deck solutions. The material and system produces a high quality, low maintenance, decking solution. It is largely made of nitrile rubber sheet which the deck pattern is cut into and filled with caulking. Small panels can be cut on a CNC machine or it can be laid in large areas and the grooves cut on site. Nitrile rubber tends to grey in UV sunlight so it is advisable to paint the deck annually with a protective coating to maintain its colour. The deck is cool and soft to walk on making it paticularly attractive to certain climates and boats.

Teak Carpet

Manufactured and designed in Britain using Deckfab patent technology. The deck design is printed onto a fabric and cut out to replicate the appearance of a traditional teak deck. It can be printed onto either a composite material or more traditional tuft carpet. It is soft to walk on like a carpet. Manufactured from a solid vinyl reinforced base with a densely packed short fibre surface of nylon strands which are anchored firmly into the base layer. A technically advanced printing process allows beautiful marine designs to be created on the surface. It is a very capable indoor/outdoor product for cockpits.