PVC Synthetic Teak

Introduction

Our aim is to transform your boat with a great synthetic teak deck using our unmatched expertise in this specialist market. We can offer independent advice to help you find the perfect option and choose which synthetic teak solution matches your needs. Our expert teams are highly skilled and fully equipped with the latest technologies, enabling them to deliver consistently outstanding results.

With over 20 years of experience in the manufacturing and installation of PVC synthetic teak decks, our experts have formulated a unique solution that caters to all your decking needs. We have a dedicated team of experienced professionals located around the UK, who are always ready to assist you with the design, manufacturing, and installation of your synthetic deck. Our product offers a durable and long-lasting solution for your decking requirements, without the need for constant maintenance.

We value our customers and are devoted to providing high-quality products and services that meet their specific needs. We take immense pride in satisfying our clients with a final product that amplifies the beauty of their boat.

Don’t wait any longer to transform your boat into a stunning decked area using Deckfab

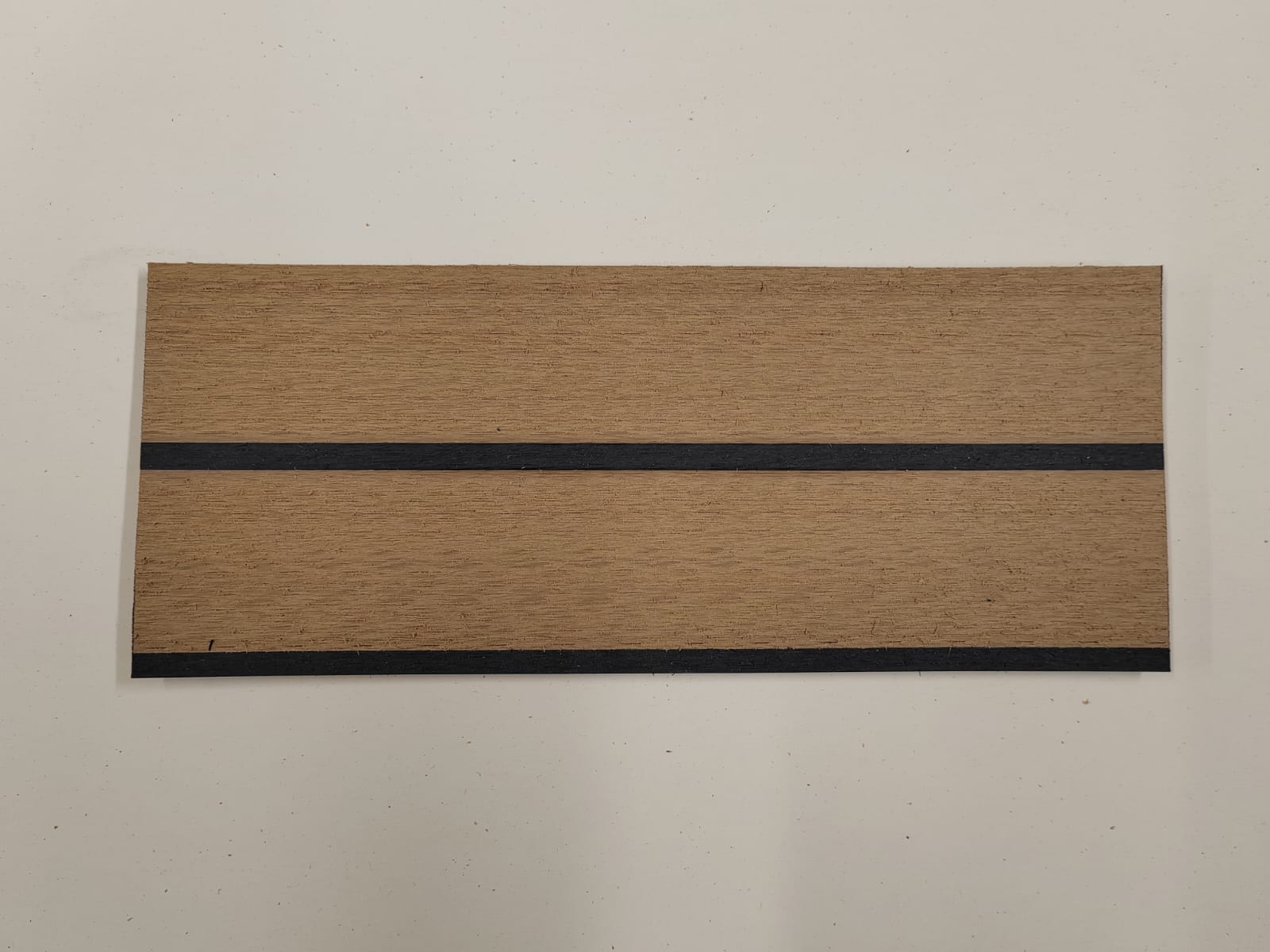

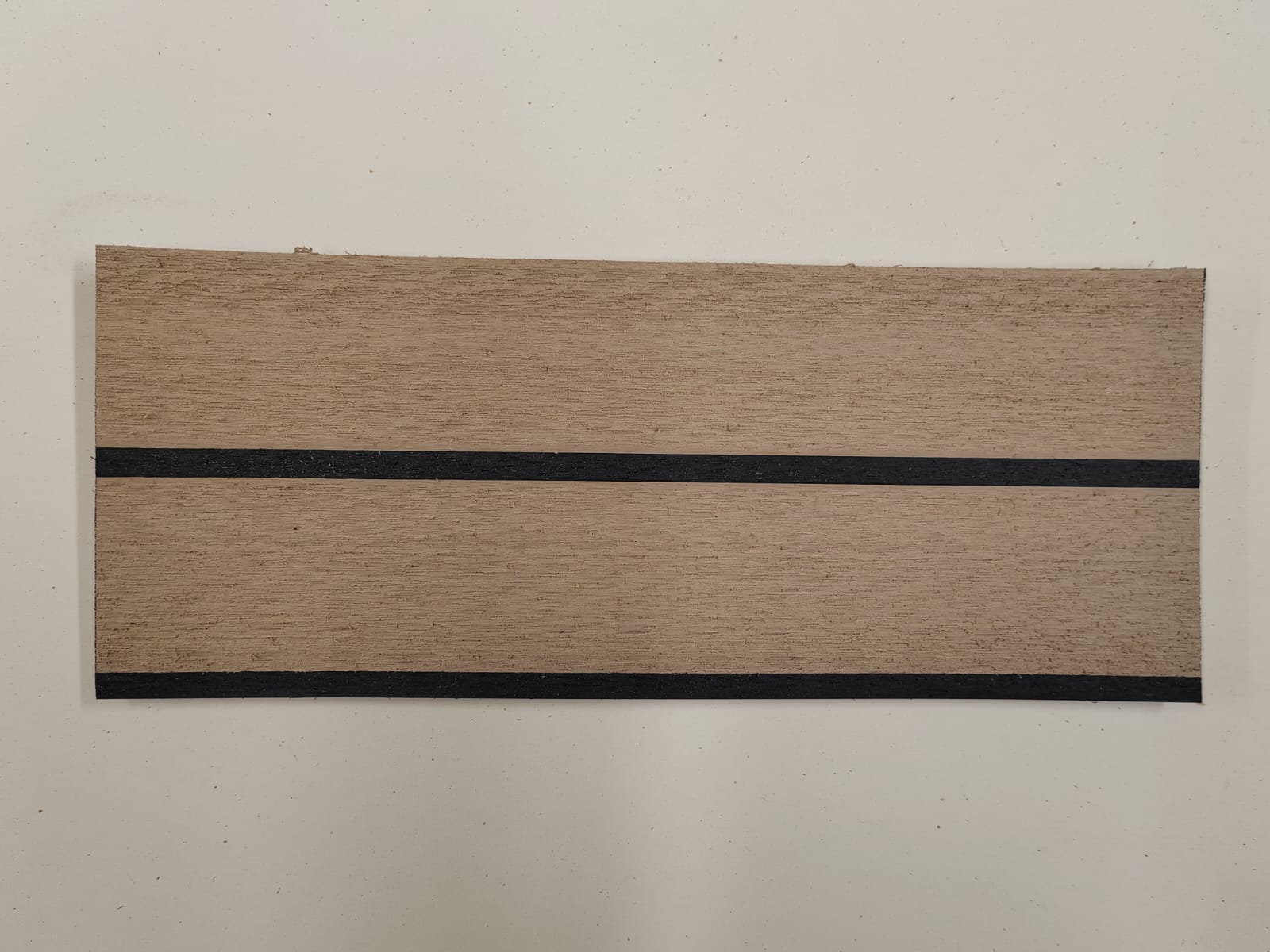

Colours

We try and not to complicate synthetic teak decking with many colours that do not look like the real thing. We concentrate on stocking the most realistic colours in various states of weathering of real teak. For example, cockpits of powerboats under tarpaulins tend to choose traditional colour, whereas sailboat cockpits exposed to the elements tend to choose weathered colour. It is wise ti remain conservative on the colour choice as it may effect resale values or reduce your chances of selling the boat. We do usually stock white caulking options too.

Traditional

Weathered

Aged

Performance

Deckfab, a synthetic decking system that offers significant advantages over rival products in the market.

One of the main benefits of Deckfab is its dovetail underside, which provides superior adhesion and a larger surface area for a mechanical bond. This unique feature sets Deckfab apart from other synthetic decking systems.

In addition to its strong bonding capabilities, Deckfab also boasts a superb multi-graining texture that resembles traditional teak. This makes it the most comparable synthetic teak decking to that of natural teak.

Durability and Guarantees

We guarantee that our original decks will remain beautiful and durable for years to come, with many of our decks being more than a decade old and still looking stunning. Our products are backed by an exceptional 6-year guarantee against material defects, which is further complemented by the additional guarantees for deck panel integrity.

We take pride in using only the best materials and manufacturing techniques. We employ cutting-edge vinyl welding techniques to create joints that are stronger than those created using glue. Our products have an extremely hard-wearing surface that is UV stable, and they can be easily re-sanded should the need ever arise.

Maintenance

Deckfab requires minimal maintenance to retain its excellent appearance. With its durable composition, it eliminates the need for regular expensive cleaning and sealing systems, making it a popular choice.

Additionally, a simple rinse or a jet wash is enough for a deep clean that restores the decking to its new-like finish. Stains caused by common spills like oil, fuel, red wine, and fish blood can be removed with soap and water, providing you with a hassle-free cleaning experience.

Synthetic Teak Material and Decking Systems

After many years of deck panel fitting all the leading material brands we now work with a decking system called Deckfab This material is 100% Virgin PVC without any additives or packing material and is extruded in the UK. The reverse has dovetails to increase the surface area for maximum adhesion to the deck. Our decking system is unique to us and produces the strongest and most durable decks. The linishing is medium grit at the factory but we sand the deck on the final finish so the customer can have a choice of texture finish prior to the panel being released to the fitter. The texture tends to smooth over time and general use. There are a range of colours with 98% of boats opting for traditional, weathered or aged teak colours so we only offer these colours which are popular because they are the most realistic.